Introduction to Silicone Rubber Refining

The industry relies heavily on silicon rubber, a versatile synthetic elastomer made of a combination of silicon, carbon, hydrogen, oxygen, and on rare occasions additional elements. Due to its distinctive characteristics, which include strong thermal and chemical resistance, flexibility across a broad temperature range, electrical insulating capabilities, and biocompatibility, it finds extensive use in a variety of sectors, including aerospace, electronics, healthcare, and automotive. The silicone rubber refining process must be morphed for it to reach its full potential. This refinement consists of altering the material’s molecular structure and modifying its properties to fit particular industrial needs. To tailor silicone rubber’s characteristics, such as hardness, tensile strength, and elongation, to various uses, it must be refined. Silicone manufacturers can modify the material, decide on the necessary parameters, and improve its use, durability, and performance through the coordinated optimization of the refining process, pushing forward the boundaries of innovation in a variety of industries.

What Are Silicone Rubber Properties?

Raw, unprocessed silicone rubber has a distinctive set of fundamental attributes that support its extensive variety of applications. Mechanically, it demonstrates astounding elasticity and suppleness, easily adjusting to temperature changes without jeopardizing its structural integrity. Due to the material’s breathtaking heat resistance, it may remain structurally sound in a variety of temperatures, from bitterly cold to searing hot.

Additionally, silicone rubber is the top choice in settings where electrical conductivity can be potentially dangerous due to its superior electrical insulating qualities. Nevertheless, despite these benefits, unprocessed silicone rubber has several drawbacks and restrictions. For high-stress applications, its mechanical strength could not be sufficient, which could result in premature wear. Furthermore, its inadequate abrasion resistance and relatively moderate tear strength may compromise its durability when exposed to friction and continuous use. Additionally, inappropriate thermal and electrical qualities could prevent them from performing well in harsh environments or from having exact electrical conductivity. To address these issues and increase the overall versatility and applicability of silicone rubber, refining methodologies have become essential.

Techniques for Silicone Rubber Refining

High-Temperature Vulcanization

The vulcanization process, which alters silicone rubber’s characteristics and broadens its range of applications, is the foundation of silicone rubber refinements. The sophisticated interaction of heat and curing chemicals is at the core of this change. Silicone rubber is heated to high temperatures during the vulcanization process, frequently in the presence of curing chemicals that include sulfur.

This controlled exposure starts a chemical reaction called crosslinking, which strengthens the links between polymer chains and strengthens the material’s elasticity and mechanical strength. Applying heat and curing agents carefully not only overcomes the drawbacks of unrefined silicone rubber but also has other advantages. The material is more resilient and durable due to its enhanced elasticity, which enables it to tolerate repeated strain without continually deforming. A reliable option for long-term applications, the material’s improved stability suggests that its qualities will remain constant over time and under a variety of circumstances. Furthermore, silicone rubber’s improved heat resistance enables it to survive hot settings without losing its structural integrity. Silicone rubber therefore goes through a journey of transformation during the vulcanization process to become a versatile and essential component in industries that demand strong materials with outstanding performance distinctive characteristics.

Addition of Fillers and Reinforcements

The introduction of diverse filler components, including silica, carbon black, etc., has emerged as a fundamental tactic in the field of silicone rubber refinement. To increase the material’s mechanical strength, wear resistance, and even electrical conductivity, these fillers are essential.

For instance, incorporating silicon dioxide into silicone rubber enhances its structure and raises the material’s tensile strength and tear resistance. Contrarily, carbon black strengthens both mechanical and electrical conductivity, making it useful for applications requiring conductive or antistatic qualities. The ideal filler loading and distribution must be carefully taken into account to achieve the desired result. Poor distribution can result in uneven material character traits, whilst overloading can cause a loss in flexibility and an increase in viscosity. Silicone Manufacturers can benefit from these fillers without compromising the material’s intrinsic properties by carefully controlling their quantity and dispersion. As a result, the strategic use of filler materials offers a way to refine silicone rubber so that it can meet the various calling criteria of a variety of industries.

Polymer Modification

One of the most successful approaches to enhance the performance of silicone polymers for particular applications is to modify their structure. Fundamental attributes like flexibility, adhesion, and chemical resistance are adversely affected by this structural tailoring. It is possible to fine-tune the material’s flexibility by varying the density of the polymer chains and crosslinks, making it the option of soft or stiff. In addition, modification can strengthen the bond between silicone rubber and a variety of surfaces and increase adhesion. Through structural changes, silicone rubber’s outstanding chemical resistance can also be tailored so it can withstand particular situations. Numerous successful case studies demonstrate the revolutionary potential of polymer modification. Silicone rubbers are distinguished by these alterations in a range of settings, from medical devices needing great biocompatibility to industrial seals needing exceptional chemical resistance. In essence, the industry may alter material qualities via modifications to the structure of silicone polymers, opening up a world of unique future possibilities to satisfy specific performance necessary information.

Benefits of Silicone Rubber Refining

On top of that, modification can strengthen the bond between silicone rubber and a variety of surfaces and increase adhesion. Through structural changes, silicone rubber’s widely recognized chemical resistance can also be tailored so it can withstand particular situations. Numerous successful case studies demonstrate the revolutionary potential of polymer modification. Silicone rubbers are differentiated by these alterations in a range of settings, from medical devices needing great biocompatibility to industrial seals needing exceptional chemical resistance. In essence, the industry may alter material qualities via modifications to the structure of silicone polymers, opening up a world of unique open doors to satisfy specific performance specifications.

Furthermore, the silicone rubber’s adaptability has been improved by enhancing its heat resistance and electrical resistance, enabling it to be used in a variety of difficult settings. No matter how tough the electrical or thermal circumstances, this improved resistance will ensure consistent performance. The capacity to adapt silicone rubber’s qualities to the unique requirements of sectors like automotive, electronics, and medical translates into a competitive edge, which is crucial. Increasing the durability of seals and gaskets, for instance, can increase the lifespan of automobiles in the automotive industry by bettering the quality of materials. In the world of electronics, improved heat resistance aids in preventing component failure and overheating, while bio-compatibility can be precisely tailored for implantable devices in the medical industry. In each of these ways, the quest for more refined silicone rubber qualities directly addresses the demands of different sectors of the economy, spurring innovation and bolstering the bar everywhere.

Applications of Refined Silicone Rubber

Automotive Industry

Silicone rubber is essential to the reliability and trustworthiness of gaskets, seals, and hoses, particularly in demanding environments like engine components. The silicone rubber’s refinement process is essential to ensuring top performance in these demanding environments.

Refined silicone rubber is used in silicone gaskets and silicone rubber seals to maintain its integrity, stop substances from entering, and ensure appropriate fluid flow. It affects the safety and longevity of the vehicle in addition to its operating effectiveness. Effective gaskets and seals keep engines running smoothly by reducing the potential of fluid leakage, which could result in catastrophic failure or engine failure.

Another benefit is that longevity is increased since the parts can endure the punishing conditions in the engine storage space. This presents the value of refined silicone rubber in improving vehicle longevity and performance, which ultimately results in improved security and dependability in transportation.

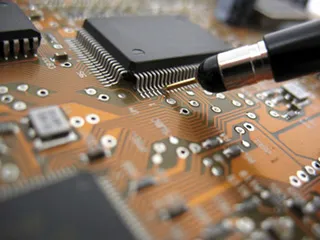

Electronics and Electrical Engineering

When functioning in demanding settings, silicone rubber is a crucial component in the design and construction of insulators, connectors, and cables. To ensure that these components are carried out superbly, silicone rubber has to go through careful modifications.

Refined silicone rubber offers confident insulation against electrical leakage or short circuits in applications needing high dielectric strength, such as electrical insulators. In connectors and cables, where temperature variations can influence electrical conductivity and general durability, its capacity to properly dissipate heat is crucial. In challenging sectors like aerospace, where severe temperatures, vibration, and radiation are generally accepted, this fragile material has found its place. Silicone rubber is an essential material for aerospace connectors, cables, and insulators because it can endure these conditions while retaining its electrical and thermal qualities. As the industry continues to push the boundaries of technology and explore challenging environments, the excellent properties of silicone rubber ensure the stability, safety, and consistent performance of critical components.

Medical and Healthcare

The process of refining silicone rubber is crucial to its extensive use in the manufacture of medical equipment, implants, and prostheses. For maximum biocompatibility and resistance to sterilizing methodologies, which are essential in medical environments, silicone rubber must be refined.

With careful alterations, silicone rubber can be made to work in harmony with the body, lowering the possibility of negative reactions. The functionality and safety of medical equipment are preserved throughout their useful lives because of their biocompatibility and resistance to sterilizing systems like autoclaving. Numerous successful case studies exist that show how silicone rubber is beneficial in a range of settings, including the creation of cozy, flexible, and long-lasting prostheses as well as implantable devices like catheters and pacemakers. A vital component of contemporary healthcare, silicone rubber’s delicate qualities enable it to meet strict requirements for medicine, improving the quality of everyday life for countless patients.

Future Trends in Silicone Rubber Refining

The range of silicone rubber development continues to grow as a result of research into new technologies and materials. This investigation aims to improve traditional qualities while also following the global trend toward eco-friendliness and sustainable development. Refining procedures use recyclable resources, energy-efficient techniques, and environmentally conscious additives as the sector places an enormous value on environmental consciousness. Potential advances in the characteristics and uses of silicone rubber will reshape several industries. The potential uses range from biodegradable medical implants to self-healing silicone rubber coverings in the automotive industry.

Silicone rubber has the potential to advance technology, industry, and healthcare by transforming how we interact with them in the future through the establishment of refining technologies and the enlargement of new materials.