EMI Conductive Elastomer

Good electrical conductivity and electromagnetic shielding performance

Conductive silicone shielding

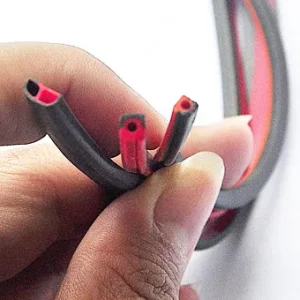

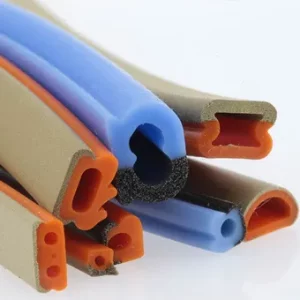

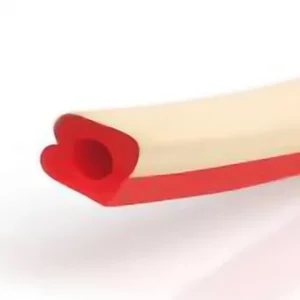

Conductive silicone rubber elastomer strips are made of silicone with metal powder filler. It is widely used because of its excellent EMI shielding effectiveness, environmental sealing, and long service life. Conductive filler is generally nickel graphite.

Electromagnetic interference (EMI), sometimes referred to as radio frequency interference (RFI).

Can be understood as a phenomenon in which one electromagnetic field interferes with another electromagnetic field, resulting in the destruction of one or both fields

It can solve the reliability problem of smart electronic equipment running in complex and harsh electro magnetic interference environments.

It can be mass-produced according to the contours required by the customer, and the interface parts are bonded by a special process to make the interface performance consistent with other parts. And add double-sided tape on the back to meet the different application requirements of customers.

To provide customers with environmental assessment failure performance and personalized counter measures and comprehensive solutions, with excellent stability performance, products are concentrated in communications equipment, aerospace, medical, electronics, machinery manufacturing, rail transportation, new energy and other industries.

EMI shielding is a barrier against electromagnetic interference, essentially protecting the electronics of a device or system. Typically consisting of a metal shield that absorbs airborne interference, either around the sensitive electronics of the device to protect it from other devices, or around the transmission electronics in the device to prevent emissions.

EMI shielding is a barrier against electromagnetic interference, essentially protecting the electronics of a device or system. Typically consisting of a metal shield that absorbs airborne interference, either around the sensitive electronics of the device to protect it from other devices, or around the transmission electronics in the device to prevent emissions.

Silicone elastomers or silicone elastomerics most often refers to silicone-based polymers that have been vulcanized. To more intuitive and descriptive, often use the term “silicone rubber” . Silicone elastomers or silicone rubber materials are readily available, from 10 durometer Shore A (soft) to 70 durometer Shore A (firm).

Rubber is easily affected by heat, chemicals, fungus, ultraviolet light and ozone, affecting its service life. Silicone has higher heat resistance properties than natural rubber, allowing for more effective insulation. Silicone has a longer life expectancy than other elastomers.

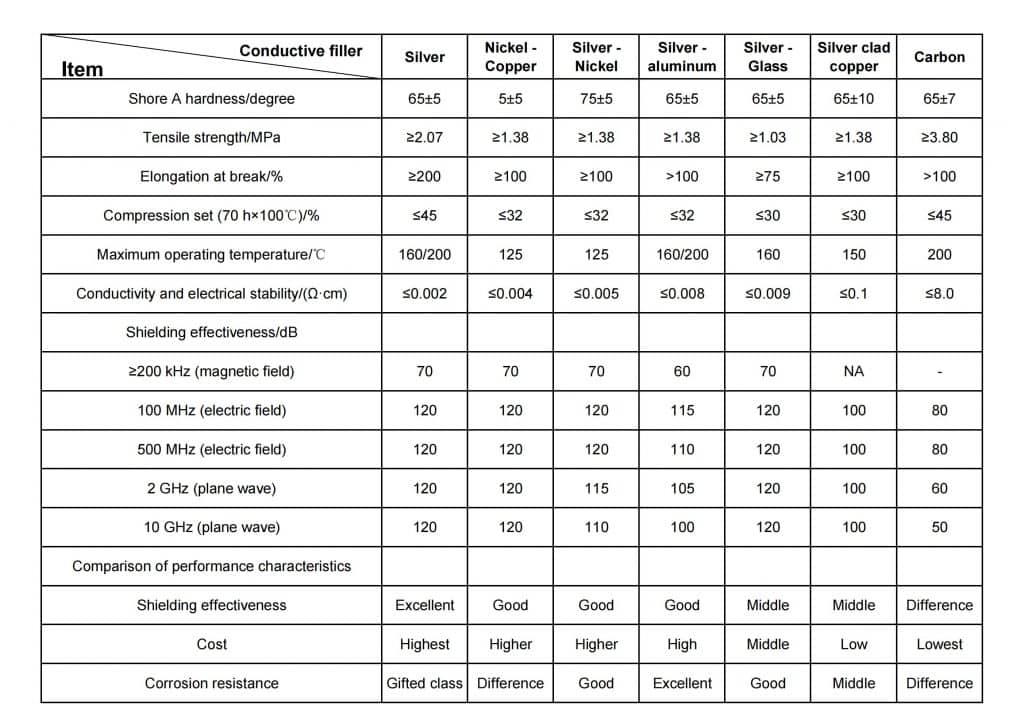

Conductive fillers

Conductive fillers are mainly nickel graphite, silver glass, silver aluminum, silver copper. In addition to controlling EMI emissions and susceptibility to silicone gaskets, conductive gaskets also function as an environmental seal. With a certain percentage of compression, it is also rainproof (NEMA Class 3), high pressure washdown resistant (IP65, IP66, NEMA 4X) and resistant to water ingress (IP67, NEMA Class 6).

The Top silicone manufacturer, in china

with 16 years of experience

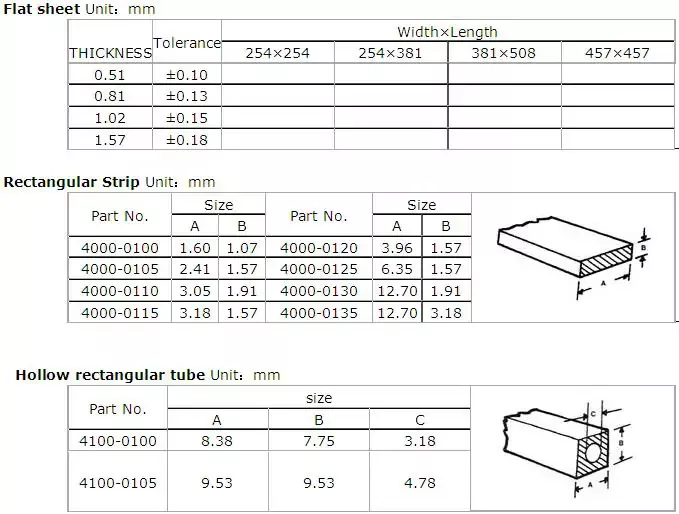

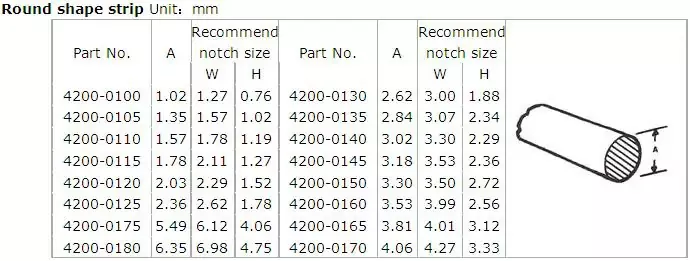

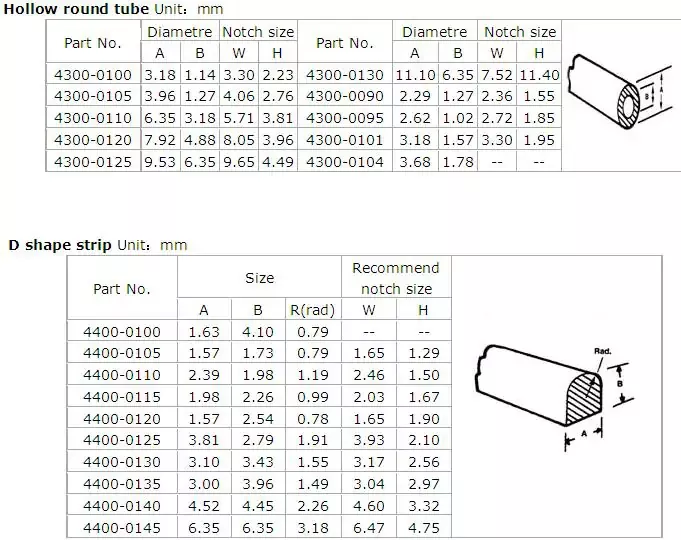

Available in standard sizes and shapes,

extruded, molded and die-cut in any shape or size

as per design and requirements.

Related Information

| Nickel-Graphite Filled Compounds – Electrically Conductive Elastomer – EMI/ESD | |||||

| PDF# | Material Name | Description | Duro “A” | Vol. Resist. (Ohm-cm) | Common Applications |

| 100 | Conductive Silicone, Nickel Graphite Filler | 30 | 0.3 | EMI Gaskets, UL 94 Rated, 36″ Wide Roll | |

| 101 | Conductive Silicone, Nickel Graphite Filler | 30 | 0.125 | EMI Gaskets, Lowest Durometer, Sheets/Molded | |

| 102 | Conductive Silicone, Nickel Graphite Filler | 40 | 0.03 | EMI Gaskets, Low Durometer, Sheets/Molded | |

| 103 | Reinforced Conductive Silicone, Nickel Graphite Filler | 40 | 0.004 | High Tensile Strength, X & Y Dimensional Stability, Continuous Sheet | |

| 104 | Conductive Silicone, Nickel Graphite Filler | 40 | 0.5 | UL 94V-0 Flame Rated | |

| 105 | Conductive Silicone, Nickel Graphite Filler | 55 | 0.05 | EMI Gaskets, Medium Durometer, Sheets/Molded | |

| 106 | Conductive Fluorosilicone, Nickel-Graphite Filler | 50 | 0.02 | Fuel Resistant EMI Gaskets, Sheets/Molded | |

| 107 | Conductive Fluorosilicone, Nickel-Graphite Filler | 60 | 0.04 | Fuel Resistant EMI Gaskets, Sheets/Molded | |

| 108 | Conductive Silicone, Nickel Graphite Filler | 65 | 0.04 | EMI Gaskets, Firm Durometer, Sheets/Molded | |

| 109 | Reinforced Conductive Silicone, Nickel Graphite Filler | 65 | 0.007 | High Tensile Strength, X & Y Dimensional Stability, Continuous Sheet | |

| 110 | Conductive Silicone, Nickel Graphite Filler | 60 | 0.3 | UL 94V-0 Flame Rated | |

| Nickel-Coated Aluminum Filled Compounds – Electrically Conductive Galvanic Corrosion Resistant Elastomer – EMI/ESD | |||||

| PDF# | Material Name | Description | Duro “A” | Vol. Resist. (Ohm-cm) | Common Applications |

| 115 | Conductive Silicone, Nickel-Coated Aluminum Filler | 68 | 0.08 | EMI Gaskets, Superior Galvanic Protection | |

| 116 | Conductive Fluorosilicone, Nickel-Coated Aluminum Filler | 72 | 0.03 | EMI Gaskets, Superior Galvanic Protection, Additional Fuel Resistance | |

| Carbon Filled Compounds – Electrically Conductive Elastomer – ESD | |||||

| PDF# | Material Name | Description | Duro “A” | Vol. Resist. (Ohm-cm) | Common Applications |

| 121 | Conductive Silicone, Carbon Filler | 65 | 5 | ESD Gaskets, ESD Pad, Sheets/Roll | |

| 122 | Conductive Neoprene, Carbon Filler | 70 | 15,000 | ESD Pad, ESD Gaskets, Medium Temperature Molding Compound | |

Material Properties of Silicone Rubber

>Long Term Compression Set Resistance

Unlike most organic elastomers, silicone maintains its resiliency over a broad temperature range and resists taking a permanent compression set.

>Electrical Conductivity

Silicone Rubber can be blended with nickel-graphite or silver plated aluminum particles for electrically conductive gaskets that provide EMI (electro-magnetic interference) Shielding for electronic communication equipment. Conductive silicone is available in sheets or custom molded gaskets.

>FDA Regulations

Silicone Rubber can be compounded by using ingredients that meet FDA regulations for properties such as high tear strength and flexing using platinum based catalysts.

>Flame Retardant Capabilities

Silicone Rubber can be compounded to be flame retardant and achieve UL94V0, UL94V1 and UL94HF1 certifications. Even when silicone rubber burns under extreme temperatures, the by-products are non-toxic and any residual ash continues to provide electrical insulation properties.

>Electro-Static Discharge (ESD)

Solid silicone rubber can be blended with semi-conductive carbon for ESD properties. Further, closed silicone will accept a surface coating of conductive silicone for soft gaskets and pads with ESD grounding properties.

>Thermal Conductivity

Silicone Rubber can be blended with ceramic powders such as alumina and boron nitride for thermal interface pads that help to dissipate heat from power generating devices in electronics.

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.

Get In Touch

- +86 177 5066 6291