Silicone Gasket & SealsManufacturer

Find quality silicone gaskets and seals from a leading manufacturer. We supply OEM parts and components to a range of industries.

Contact To Get Your Free Quote

Privacy Policy

Security and Privacy Guaranteed 100%!

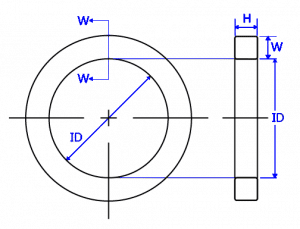

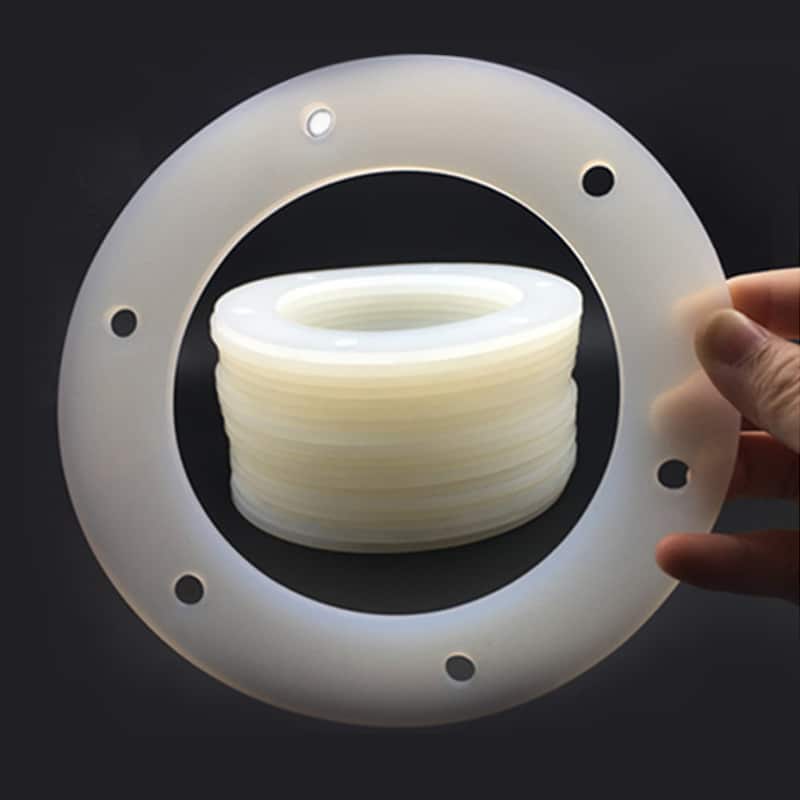

Silicone rubber Gaskets

Description & features:

Silicone seals keep the two substances tightly bonded without friction by filling the gap between the two substances. Gaskets and washers can be used as independent parts to protect the surface of the connecting part from being scratched by the main part and play a sealing role.

Contact To Get Your Free Quote

Privacy Policy

Security and Privacy Guaranteed 100%!

What is a silicone rubber gasket?

Silicone rubber gaskets are high performance mechanical seals with the ability to maintain flexibility and low compression permanent characteristics over the widest operating temperature range. The main application is to prevent leakage between different substrate parts. Newtop has the facility to manufacture standard gaskets and gasket sizes (specialized design is the team) as well as in-house custom parts, each made from the highest quality silicone gasket material.

Product category

Custom Gaskets Newtop offers molded silicone gaskets and seals. Key custom molding capabilities include compression molding, transfer molding, and silicone liquid injection molding. Customized different sizes and different colors are available upon request.

Custom Gaskets Newtop offers precision die cut conductive silicone gaskets and seals. Conductive silicones are commonly used in electronic applications. Thermally or electrically conductive by filling with special conductive fillers such as; carbon, nickel, silver aluminum, silver and copper.

Custom Gaskets Newtop offers precision die cut and molded FDA (food grade) silicone rubber gaskets and seals. Food-grade silicone products meet your specific application and are reliable in temperatures ranging from -175°F to 482°F. Food-grade silicones are odorless, odorless, peroxide-free and anti-fungal, making them ideal for applications where food is present.

“One Stop Solution” for all your Silicone Product Requirements

Contact To Get Your Free Quote

Privacy Policy

Security and Privacy Guaranteed 100%!

Silicone gasket range

- Insertion silicone gaskets

- Platinum cured silicone rubber gaskets

- Metal detectable silicone gaskets

- Flame retardant silicone gasket grades

- Silicone rubber gaskets with 40° hardness

What's the different of silicone material?

Describe

An elastomer composed of silicon, oxygen, hydrogen, and carbon, silicones are known for their ability to maintain flexibility and low compression set characteristics over the widest range of operating temperatures.

The main purpose

Static sealing in extreme temperature situations.FDA compliant for use in medical device seals.

Has low outgassing and excellent damping properties.

Temperature range

Standard Compound: -85°F to +400°FSpecial Compounds: -148°F to +400°FHardness (Shore A): 5 to 80

Feature

Specially compounded silicones perform to -148°F.Metallic fillers and conductive carbon black make silicones conductive for use in EMF/RF applications.

LSR is a low-viscosity silicone elastomer with high thermal stability and flexibility at low temperatures, high transparency and easy coloring for liquid injection molding (LIM) equipment. Also available are self-lubricating and conductive grades as well as FDA and medical compliant grades. Liquid silicone rubber is very suitable for the molding of complex profiles due to its excellent flow characteristics. See Silicones for other key benefits.

Capable of meeting USP Class VI and ISO 10993 requirements and can be sterilized by autoclave, gamma, ETO. Implants less than 30 days old and long-term implant grades available. Medical grade pigments are also available.

Limitations: Generally, the low abrasion and tear resistance and high friction properties of silicones cannot effectively seal some dynamic applications. At the same time, silicone is also highly gas permeable and is generally not recommended for use in contact with ketones (MEK, acetone) or concentrated acids.

Products Review

Customized sealing rings with different shapes, sizes and colors

Materials for different applications

Newtop-Material-Datasheet-S1000

General purpose and FDA compliant Silicone per 21 CFR 177.2600 (available in nearly any color and durometer)

Newtop-Material-Datasheet-S1004

General purpose softer than standard Silicone to seal rough or warped glands and or low closure force applications.

Newtop-Material-Datasheet-S1015

Higher temperature resistant Silicone.

Newtop-Material-Datasheet-S1015

Higher temperature resistant Silicone.

Newtop-Material-Datasheet-S1020

Clear-Translucent and FDA compliant Silicone per 21 CFR 177.2600.

Newtop-Material-Datasheet-S1146

Medical Grade USP Class VI and FDA compliant Silicone, Platinium Cured, Commercial Manufactured.

Newtop-Material-Datasheet-S1004

General purpose softer than standard Silicone to seal rough or warped glands and or low closure force applications.

Newtop-Material-Datasheet-S1037

Medical Grade USP Class VI and FDA compliant Silicone, Platinium Cured, Clean Room Manufactured

Newtop-Material-Datasheet-S1015

GeneralLower temperature resistant Silicone.

The Top silicone manufacturer, in china

with 16 years of experience

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.

Get In Touch

- +86 177 5066 6291