Electromagnetic shielding is now a crucial manufacturing aspect for modern vehicles, particularly those with self-driving technology. Such Electromagnetic Interference (EMI) shields aim to protect electronic equipment within the vehicle from interference and ensure electromagnetic immunity. Without proper shielding, electric vehicles and smart cars pose significant safety risks, with components likely to malfunction and cause equipment errors, endangering occupants and other drivers on the road. In this article, we’ll explore what you should know about EMI shielding’s importance in smart car manufacturing.

What is EMI shielding?

EMI shielding or electromagnetic interference shielding is a technology used to protect electronic devices and systems from external electromagnetic radiation. This radiation can come from a variety of sources, such as radio waves, microwaves, and other electronic devices, causing interference, failure, and even damage to sensitive components.

Electromagnetic interference (EMI) originates from both natural and man-made sources. It’s imperative to shield electronic devices from EMI both from external sources and from within the devices themselves.EMI shielding is typically achieved by using a conductive metal enclosure, such as steel or aluminum, or by plating a non-conductive material, such as plastic, with a conductive media. These materials form a Faraday Cage around the emitting device, limiting or eliminating EMI emanating from the enclosure. A shielding gasket must be added to complete the conductive path necessary to achieve the Faraday Cage. Without the completion of this shield, EMI can be amplified, which will lead to more issues.

Without electromagnetic shielding material, electronic devices will not function correctly. For instance, a wifi router emits a signal that allows devices to connect and stream data. In the presence of another device lacking EMI shielding, regardless of frequency, the router signal can interfere with the device’s performance, including its antenna system, and cause the router to lose functionality, ultimately leading to various malfunctions in both systems.

The Critical Applications of EMI Shielding

EMI (Electromagnetic Interference) electronic shielding is crucial in various applications to ensure the proper functioning and performance of electronic devices and systems. Some of these applications include:

Aerospace and Aviation: Aircraft, satellites, and other aerospace systems rely on accurate communication and navigation equipment. EMI shielding protects these sensitive components from external interference, ensuring safe and reliable operation.

Medical Devices: EMI shielding is essential for medical equipment such as MRI machines, ECG monitors, and implantable devices like pacemakers. Proper shielding prevents interference that could lead to misdiagnosis or malfunctioning devices, ensuring patient safety and accurate results.

Telecommunications: In the telecommunications industry, EMI shielding helps prevent signal interference and crosstalk between different devices and networks. This ensures clear and uninterrupted communication for users.

Automotive: Modern vehicles are equipped with numerous electronic systems for engine control, safety, and entertainment. EMI shielding is crucial for protecting these systems from interference, ensuring optimal performance, and reducing the risk of malfunctions.

Military and Defense: Military equipment and systems often operate in environments with high levels of electromagnetic interference. EMI shielding protects sensitive electronics, ensuring reliable communication, navigation, and weapon systems functionality.

Consumer Electronics: Devices such as smartphones, tablets, and laptops require EMI shielding to ensure smooth operation and prevent interference from other electronic devices or radio frequency sources.

Industrial Automation: In automated manufacturing environments, EMI shielding is critical for protecting sensors, controllers, and other electronic components from interference. This ensures the accurate and consistent functioning of the automation systems.

Data Centers: EMI shielding is essential for data centers to protect servers, switches, and other networking equipment from external electromagnetic interference, ensuring reliable data transmission and storage.

Power Systems: Power generation and distribution systems require EMI shielding to prevent interference that could lead to equipment malfunction or failure, ensuring stable and consistent power delivery.

Scientific and Research Equipment: EMI shielding is necessary for sensitive research instruments, such as oscilloscopes, spectrometers, and electron microscopes, to ensure accurate measurements and prevent data corruption.

Silicone Material Options for EMI Shielding Components

Silicone materials are widely used for EMI (Electromagnetic Interference) shielding due to their excellent flexibility, temperature resistance, and durability. Various silicone material options can be combined with conductive fillers to create effective EMI shielding solutions. Here are some common options:

Conductive Silicone: Conductive silicone is a blend of silicone rubber and conductive particles such as silver, nickel, aluminum, or carbon. This combination provides good electrical conductivity and EMI shielding effectiveness while maintaining the desirable properties of silicone.

Electrically Conductive Fluorosilicone: This material combines the chemical resistance of fluorosilicone with the electrical conductivity of conductive particles. It is ideal for applications that require both EMI shielding and resistance to fuels, oils, and other harsh chemicals.

Silicone-Coated Fabric: Silicone-coated fabrics are made by applying a thin layer of silicone onto a fabric substrate, such as fiberglass or polyester. Conductive particles can be added to the silicone coating to provide EMI shielding. These materials are lightweight, flexible, and can be easily cut and shaped to fit various applications.

Metal-filled Silicone Gaskets: Metal-filled silicone gaskets are made by combining silicone with metal particles, such as silver, copper, or nickel. These gaskets offer excellent EMI shielding performance and can be customized to fit a wide variety of applications.

Silicone Foam: Silicone foam can be infused with conductive particles to create a lightweight, flexible, and compressible EMI shielding material. This option is ideal for applications that require cushioning or sealing, in addition to EMI protection.

Magnetic Silicone: Magnetic silicone materials are created by blending silicone with magnetic particles, such as iron or ferrite. This type of material can provide EMI shielding by absorbing and containing electromagnetic energy.

When selecting a silicone material for EMI shielding, consider factors such as the required shielding effectiveness, environmental conditions, and mechanical requirements of your application. It is essential to consult with an EMI shielding specialist or materials engineer to determine the most suitable material for your specific needs.

Common EMI Shielding Tools & Techniques

EMI (Electromagnetic Interference) shielding is crucial for protecting sensitive electronic components from unwanted electromagnetic radiation. It involves using various tools and techniques to reduce or block the effects of EMI. Here are some common EMI shielding tools and techniques:

Shielding Enclosures: Metal enclosures made of materials like aluminum, steel, or copper provide excellent EMI shielding by creating a conductive barrier around the electronic device.

Conductive Coatings: These coatings, typically made of metals like copper, nickel, or silver, can be applied to non-conductive surfaces, such as plastic or glass, to create a shield against EMI.

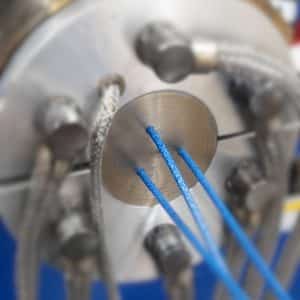

EMI Gaskets: Gaskets made from conductive materials, like metal-filled silicone, elastomers, or foam, are used to seal gaps between enclosure parts and ensure proper EMI shielding.

Shielded Cables: Shielded cables have a conductive layer, usually made of a metallic braid or foil, that surrounds the signal-carrying wires to protect them from EMI.

Ferrite Beads: These small, cylindrical components are made of ferrite material and can be added to cables or circuit boards to suppress high-frequency EMI.

Filtering Components: Capacitors, inductors, and ferrite cores can be used to filter out EMI noise in electronic circuits.

PCB Layout Optimization: Properly designing the layout of a printed circuit board (PCB) can help minimize EMI. Techniques include separating analog and digital sections, using ground planes, and minimizing loop areas.

Faraday Cages: A Faraday cage is an enclosure made of conductive material that surrounds an electronic device and blocks external EMI. They are commonly used in testing environments to isolate devices from external interference.

EMI Absorbers: These materials can be attached to a device or enclosure to absorb and dissipate EMI energy, reducing the overall EMI within the system.

By employing these tools and techniques, you can effectively shield your electronic devices from EMI and ensure their proper functioning.

EMI Shielding Gaskets in Automotive Industry

EMI shielding gaskets offer an economical approach to creating a Faraday Cage that minimizes signal interference.

The automotive industry is rapidly evolving, with increased demand for sophisticated and connected vehicles thanks to advancements in technology. Thus, modern vehicles rely heavily on electronics for their various functions such as engine control, safety systems, and infotainment. To ensure the smooth and efficient operation of these systems, electromagnetic interference (EMI) shielding is now a critical aspect.

One of the popular EMI shielding products in use today in the automotive industry is gaskets. These gaskets, made of conductive materials such as metal or conductive elastomers, create a barrier to prevent electromagnetic radiation from interfering with electronic devices’ operation. As the role of electronics in cars advances, EMI shielding gaskets will also undergo several trends shaping the automotive industry’s market.