Products made of silicone have become significant in an assortment of businesses, including healthcare, electronics, and food manufacturing. They are a preferred option for manufacturers throughout the world due to their capacity for adaptation and distinctive qualities. To ensure their safety and quality, however, a rigorous certification procedure needs to be followed due to the widespread use of silicone products. This blog aims to enlighten readers about the critical function that certification serves in ensuring that silicone products adhere to the required requirements. The goal of this article is to give readers an extensive understanding of certification, its importance, and the advantages it offers to both producers and consumers. Join us on this thrilling journey as we debunk some of the rumors surrounding silicone product certification and investigate the reasons why it is an essential component of numerous companies.

What Are Silicone Products?

The particular synthetic polymer known as silicone has become famous for its exceptional characteristics that set it apart from other materials. It is a flexible and heat-resistant material made up of silicon, oxygen, carbon, and hydrogen atoms. Silicone is very versatile because of its unique properties, among them its extraordinary resistance to stern temperatures, UV radiation, and chemicals. Silicone is a component that we come into coming into contact with daily in a variety of products, from personal care items like silicone-based skincare to kitchen tools like spatulas and baking mats.

Silicone has an extensive number of uses outside of the home and is essential to many different industries. Due to its biocompatibility, silicone is commonly used in healthcare to make healthcare implants and equipment. These instances demonstrate silicone’s numerous and varied uses in the contemporary world, proving its versatility as well as importance in how we live every day.

Types of Silicone Product Certifications

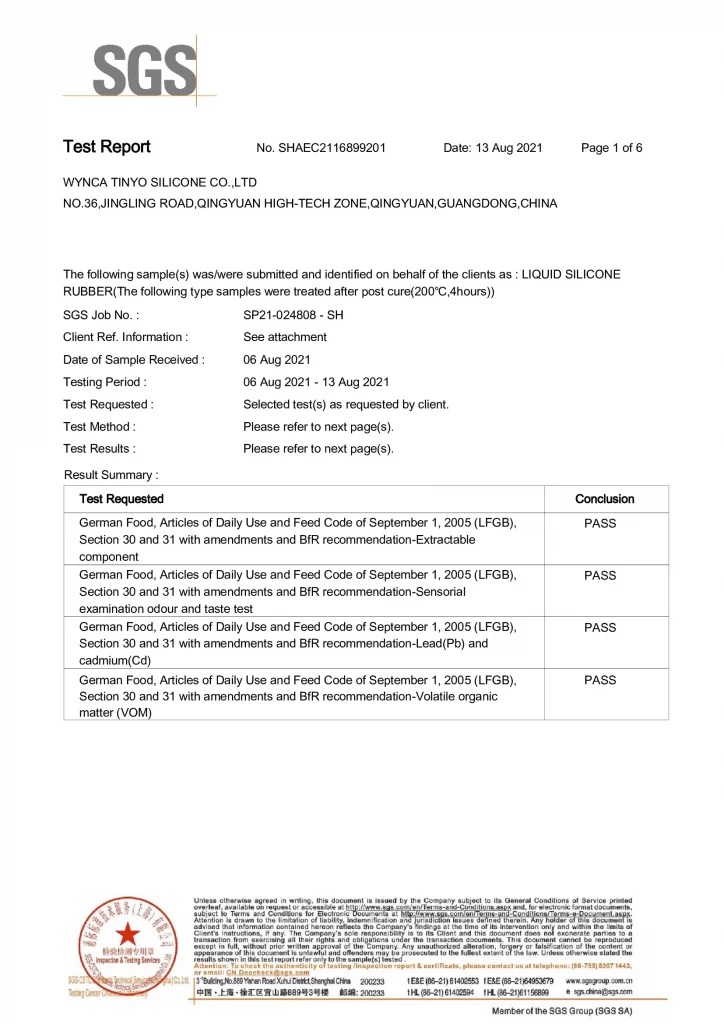

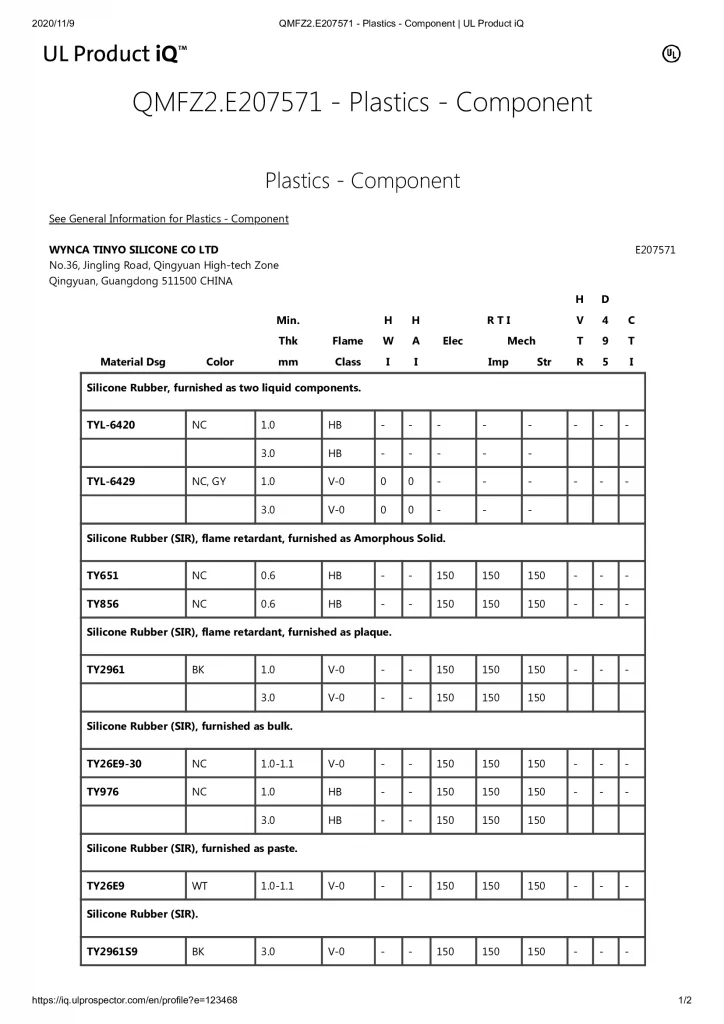

The safety and high caliber of silicone products have been guaranteed substantially by several significant certification government officials and organizations. The Food and Drug Administration (FDA), Conformité Européenne (CE), and Underwriters Laboratories (UL) are a few of the most widely recognized. Each of these organizations has particular requirements as well as regulations that are geared to the sector they serve. For instance, the FDA imposes strict guidelines for silicone used in medical equipment, with special emphasis on bio-compatibility and material purity. To ensure that they adhere to European Union directives, products bound for the European market must get CE certification. For silicone components in electronic products, in particular, UL demonstrates electrical and fire safety. These credentials’ dependability has been attested to by the fact that these credentials are recognized throughout. Products with these certifications are trusted not only in the nations where they are manufactured but additionally recognized and accepted around the world, giving decision-makers as well as consumers alike a sense of certainty and trustworthiness. Whereas consumer safety is of the utmost importance for both businesses, their regulations are particular to their markets and spots, making it essential for manufacturers to follow the appropriate instructions when selling products in such locations.

What is the Difference Between FDA and LFGB?

There are two major food-grade standards for silicone products: LFGB and FDA. The German Food, Commodities and Feed Code, or LFGB (Lebensmittel-Bedarfsgegenstande-und Futtermittelgesetzbuch), and the FDA (Food and Drug Administration) differ principally in their geographical purviews and the specific requirements that they establish. The U.S. regulatory agency called the FDA is responsible for making sure that food, medications, medical equipment, and cosmetics are safe and of high quality throughout the country. It imposes requirements and limitations for commodities offered on the continent’s market. In contrast, the LFGB is a set of German laws and standards that apply to products that are brought into contact with food, such as cookware and utensils, and they have a particular emphasis on the German market. The primary distinctions lie in their international reach and the particular requirements they impose.

Why Certification Matters?

It is inconceivable to fail to recognize the many other serious risks that come from using silicone products that are not certified. Lack of proper certification increases the risk of product imperfections contaminants in the raw materials, and subpar safety standards. Although open to change, silicone can pose a risk if it is not produced and managed care. To guarantee compliance, safety, and trustworthiness, certification becomes crucial. Thorough testing, quality control, and adherence to industry standards are all necessary to obtain certification, all of which result in a product that is both safer and more dependable. Examples from the real world demonstrate the significance that certification for the avoidance of difficulties. The essential requirement of certification is illustrated through incidents where substandard silicone components in electronics resulted in malfunctions or un-certified silicone medical implants have generated health issues. We can avoid the aforementioned issues and protect the reliability and security of silicone goods across a wide range of industries through adherence to these established standards.

The Certification Process

The certification of the procedure for goods made of silicone is a thorough one that includes numerous important elements. The FDA, CE, UL, or any other desired certification body’s particular guidelines must first be thoroughly investigated by manufacturers. Following thorough product development and testing, this research is used to make sure that the silicone product corresponds with the high standards established by the selected certification organization. In ensuring that you accurately put together and submit for review all product specifications, test results, and compliance records, documentation is required. The certifying organization will often audit the making process and the quality of the product as part of the certification procedure. Before certification gets granted, aware audits might need to be amended or enhanced. Depending on what kind of certification is sought, the sector, and the product, the certification process could take several months. The expenditures involved with certification can be significant and include those for testing, generating paperwork, spending for examinations, and ongoing compliance efforts. However, certification usually compensates for itself in terms of enhanced product quality, safety, and marketability.

Benefits of Certified Silicone Products

One of the most important variables in enhancing silicone product quality is certification. It acts as a strict quality assurance procedure that makes sure the goods adhere to particular industry norms and rules. Manufacturers are forced to concentrate on increasing their product development, materials, and production procedures to comply with these stringent criteria. As a result, silicone goods are now more dependable, durable, and consumer-safe.

In addition, accreditation gives a significant advantage in competition. Certified goods give consumers confidence and trust in addition to giving them a competitive edge in the market. They choose approved products over alternatives that aren’t certified when they deem certified products to be of higher quality.

In simple terms, silicone product certification is necessary for ensuring product quality, safety, and competitiveness in the market. It entails rigorous inspection and adherence to industry standards developed by bodies like the FDA, CE, and UL. Choosing certified silicone products helps you gain market share and customer confidence. We passionately encourage readers to think about considering certification for their silicone products, since it not only enhances quality but also guarantees safety in a market that is becoming increasingly aggressive.