Newtop Silicone products

Silicone Gasket & Seal-Newtop

Silicone gasket selection factors

When choosing a silicone seal, the first thing to consider is its tensile strength, constant tensile stress, elongation at break, permanent deformation at break, stress-strain curve, etc. These are collectively referred to as tensile strength. Tensile strength is actually the maximum tensile stress at which the sample breaks in tension. Constant elongation stress is the stress achieved at a specific elongation. Elongation is the deformation caused by tensile stress expressed as a percentage of the ratio of the elongation increment to the original length. Elongation at break is the elongation at break.

In addition, we also need to consider the basic properties of silicone seals. Hardness is the performance of rubber’s ability to resist external pressure. The hardness of rubber is partly related to other properties. For example, the adhesive has high hardness, high strength, low elongation, good wear resistance and poor low temperature resistance. High hardness rubber resists crushing and damage under high pressure. Therefore, the appropriate hardness should be selected according to the working characteristics of the parts.

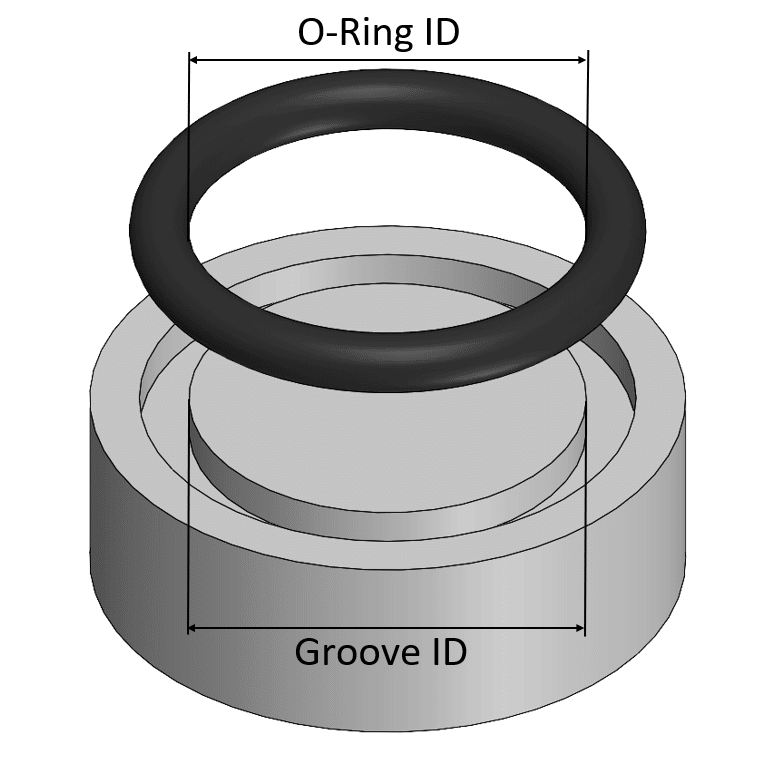

O-ring special attention conditions

The selection of the sealing ring is of great significance to its sealing performance and service life. The performance of the material directly affects the performance of the sealing ring. In addition to the general requirements for sealing ring materials, the following conditions for O-rings should be noted:

(1) Elasticity and elasticity;

(2) Appropriate mechanical strength, including expansion strength, elongation and tear strength, etc.

(3) The performance is stable, it is not easy to expand in the medium, and the thermal shrinkage effect (Joule effect) is small.

(4) It is easy to process and form, and can maintain accurate size.

(5) Do not corrode the contact surface and the contaminated medium.

>> Learn more about us to get the solution

Silicone EMI Shielding

Material Properties of Silicone Rubber

Long Term Compression Set Resistance

Properly designed Silicone Foam and Silicone Sponge outdoor enclosure gaskets can effectively seal out wind driven rain and dust – helping the designer meet NEMA enclosure and IP specifications. Unlike most organic elastomers such as EPDM and neoprene, silicone maintains its resiliency over a broad temperature range and resists taking a permanent compression set.

Silicone Elastomer Type

Metallized Filled Silicone is a molded silicone elastomer filled with conductive inert particles. It provides high electrical conductivity, broadband shielding and moisture sealing. Newtop offers these elastomers filled with: Nickel Graphite (52), Nickel (60), Silver-Plated Glass (61), Silver-Plated Aluminum (62), Silver Aluminum (63) Floro-Silicone Aluminum (64), Silver-Plated Nickel (65), Silver (66). Metallized Filled Silicone is designed to provide reliable and cost-effective shielding for a wide range of EMI applications. Metallized Filled Silicone is manufactured in sheets, molded parts, strips and die-cut flat gaskets.

- Aluminum silver-plated conductive rubber: excellent shielding performance and anti-smoke performance;

- Copper silver-plated conductive rubber: has the best conductivity;

- Glass silver-plated conductive rubber: the best cost performance;

- Sterling silver conductive rubber: has good mold resistance.

We can choose different shapes of rubber strips according to the design requirements of customers to achieve the effect of shielding and sealing for customers. Usually we provide A , B, C, D, M shape etc.

Material Properties of Silicone Rubber

The rubber is made conductive by incorporating small conductive carbon particles throughout the material. It can provide an EMI-proof and watertight seal in narrow constructions.

Due to its quite excellent conductivity, grounding, and EMI shielding effect, it is well suited for ESD application in electronics equipment. The rubber can be manufactured in various shapes such as sheets, molded parts, die-cut, strips, o-rings, etc.

Get your solutions in a flash!

Our professional service is here to help. Get the job done quickly and efficiently with our top-notch professional services!

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.

Get In Touch

- +86 177 5066 6291