Is Silicone Rubber A Right Choice for Gasket and Seals Manufacturing?

I. What are Gasket and Seal?

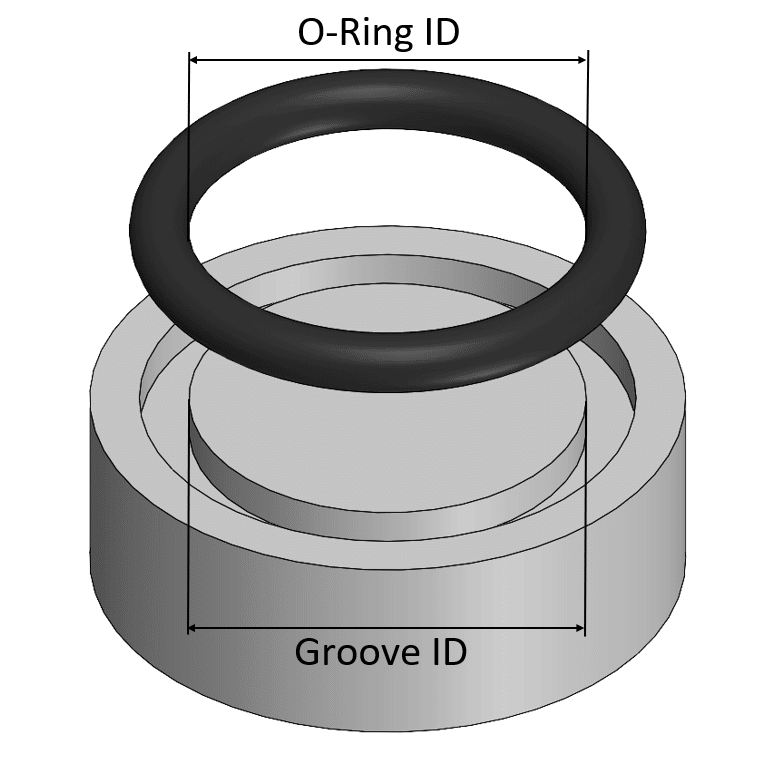

A gasket is typically a multi-functional seal part that is applied to prevent liquid or gas leakage between two solid mating surfaces. It can provide a strong defense against extreme environmental conditions or other elements. There are many applications for gasket and seal, which cover almost every manufacturing industry, from automotive, electronics, and clinical diagnosis to household, health care, etc.

While there are different types of gaskets, engineers and manufacturers are top fans of because they offer a range of good characteristics, such as higher flexibility, good tolerance to various chemicals, wide temperature range support, excellent weather resistance, better tensile strength, resilience, hygiene, longer durability, and more. In addition, gaskets of different sizes, shapes, and geometers can be produced using different elastomer materials, depending on the applications.

Seals, on the other hand, are used in active or mobile environments such as rotating shafts, engines, and motors, where they need to resist leakage, and pressure or protect the system from contamination. If the seal is damaged, the entire body of the system has to be removed to alter the seal part.

II.Is silicone rubber the right choice for gasket and seal manufacturing?

The answer is positive. Silicone Rubber Gaskets and Silicone Rubber Seals have similarities in that they both prevent any spilling or leakage.

Silicone rubber has certain characteristics that make it suitable for aerospace, automotive, energy, lighting, electronic and electrical, power generation, and other industries of all kinds of components of the perfect choice. Not only that, but its unique properties make it also used in medical, pharmaceutical, food, and beverage because, on the whole, it is non-toxic and hygienic. Here are some of the features that make it stand in a priority place.

·Ideal sealing solution

Silicone rubber can withstand a wide range of extreme weather conditions and remain retains its elasticity and compressibility, making it the best choice for manufacturing seals for extreme temperature environments. Silicone rubber seals are mostly unaffected by chemicals, gases, or moisture and do not change their physical properties.

·Stability of heat

Compared with other synthetic rubbers, silicone rubber has better durability and stability against heat and can be exposed to extremely hot or cold weather conditions or environments.

·Electrical insulation

Top-class silicone rubber is widely used in the domestic and commercial transmission of high-voltage current insulation, and flame retardant and provides better performance.

·UV, Ozone resistance

When exposed to weather conditions such as heavy wind and rain, and even under the influence of ozone, the silicone rubber’s effectiveness remains unchangeable.

Because of these factors, silicone rubber is an ideal elastomer widely used by engineers and manufacturers.

III. What Points do You Need to Consider While Customizing A Gasket?

Customizing a gasket is not an easy step. There are some factors should take them into your consideration.

Working condition.

This is the first factor you need to consider when you start to customize your gasket. Considering the weather and temperature range, your gasket will be exposed to weather conditions during its all life. It is also necessary to consider whether there is any movement and speed of the working pressure and sealing environment.

(2) Machine assembly.

The second aspect you should consider is where and why gaskets are used. Is it going to be used to seal the pipes together or use to reduce moisture and moisture? Depending on the specific application and location of the gasket, there are different designs and material specifications.

(3) Sealing for what.

The third most important factor you need to consider is the type of liquid, gas, or chemical the gasket will be exposed to. Typically, the hardness of gaskets designed to seal gases is harder than one of the liquids. After determining the temperature and pressure range, checking the chemical resistance of the gasket material is important as it will affect the structure and functional characteristics of the gasket.

If you still have no idea about customizing your gasket, I will help you. We are a professional silicone rubber manufacturer for gasket manufacturing for many years. We can support you with comprehensive custom service as per your needs.